Table of Contents

Natural Stone Fabrication: From Quarry to Countertop

The natural stone fabrication process is a fascinating blend of age-old craftsmanship and modern technology, transforming raw stones harvested from quarries into the elegant surfaces we adore. In this article, we’ll delve into each step of this intricate process, exploring how skilled artisans and advanced equipment work together to bring the beauty of the earth into our living spaces. Join us as we uncover the story behind the stone, from its extraction to its final installation, and appreciate the artistry of creating truly breathtaking natural stone products.

Understanding the Quarry Extraction of Natural Stone

Quarry extraction of natural stone is a complex and multifaceted process that involves carefully removing stone blocks from the earth and transforming raw materials into beautiful, usable products. The journey begins with identifying a suitable quarry site, often determined by geological surveys that reveal the presence of high-quality stone deposits, such as granite, marble, or limestone. Once the site is selected, extensive planning is required to ensure that the extraction is carried out environmentally while adhering to regulatory requirements. The extraction process typically utilizes various techniques, including drilling, blasting, and diamond wire saws, to liberate the stone without causing excessive damage to the surrounding environment or the stone itself.

Fabrication Process

After the stone blocks are extracted, they undergo the Natural Stone Fabrication Process, which is pivotal in transforming rough blocks into finished products suitable for commercial and residential applications. This process involves several steps, including cutting, shaping, and polishing, where skilled craftsmen and advanced machinery work together to achieve the desired specifications. Attention to detail is crucial during this phase, as the finish’s quality dramatically influences the final product’s perceived value. Fabrics can range from countertops and tiles to monumental structures and intricate carvings, each requiring specialized techniques tailored to the stone type and intended use.

Sustainability

Sustainability has become a pressing concern in the quarrying industry, prompting many operators to adopt practices that minimize environmental impact. This includes implementing measures to reduce waste, such as reusing scrap stone in landscaping or construction projects and investing in energy-efficient machinery to lower the carbon footprint. Additionally, some quarries rehabilitate landscapes post-extraction, creating new habitats for wildlife or recreational areas for communities. By incorporating such practices, the natural stone industry can contribute to a more sustainable future while still meeting modern architecture’s aesthetic and structural demands.

Ethical Quarrying Practices

Overall, understanding the quarry extraction of natural stone provides insights into the intricate balance between resource extraction and environmental stewardship. The combination of traditional craftsmanship and modern technology in the Natural Stone Fabrication Process ensures that the beauty and durability of natural stone can be appreciated for generations to come. As consumers become increasingly aware of the sourcing and production processes behind their materials, the significance of ethical quarrying practices will undoubtedly continue to grow, fostering a stronger connection between natural resources and human innovation.

The Journey of Raw Stone Blocks to Fabrication Facility

The journey of raw stone blocks to a fabrication facility is a complex and fascinating process that showcases the inherent beauty of natural stone while highlighting the skills of artisans and craftsmen. It all begins in quarries in various regions worldwide, where massive stone blocks are extracted from the earth. These blocks can include a variety of stones, such as granite, marble, and limestone, each with its unique characteristics and colors. The extraction process requires precision and careful planning to ensure that the stone is removed without damage, often involving heavy machinery and specialized tools.

Transporting the Stone Blocks

Once the raw stone blocks are quarried, they are transported to fabrication facilities, where the natural stone fabrication process truly comes to life. Skilled workers assess the blocks for suitability and aesthetic qualities at this stage. They then utilize advanced cutting and shaping equipment to create slabs from the raw stone. This part of the journey is crucial, as it transforms a rough, unrefined block into a product ready for use in various applications, including countertops, tiles, and architectural features.

Finishing Process

After the slabs are cut, they undergo a series of finishing processes, including polishing, honing, and applying protective sealants. Each step enhances the stone’s appearance and durability, allowing the artisans to bring out its natural beauty while ensuring it can withstand the rigors of daily use. Throughout this timeframe, attention to detail and craftsmanship are paramount; subtle variations in color and texture can be highlighted, resulting in unique pieces that reflect the stone’s character.

Final Phase of the Journey

The final phase of the journey culminates in creating stunning natural stone products ready to be shipped to showrooms, contractors, and homeowners alike. With a blend of technology and artistry, the natural stone fabrication process delivers exquisite materials and underscores the connection between nature and design. As consumers embrace the charm and elegance of natural stone, the entire journey—from the quarry to the fabrication facility—becomes a testament to sustainability, skill, and the timeless appeal of natural earth materials.

Cutting and Shaping: Precision Work in Stone Fabrication

In construction and design, the art of stone fabrication stands as a testament to nature’s raw beauty and humanity’s creative ingenuity. Cutting and shaping natural stone is a meticulous process that combines traditional techniques with modern technology, elevating stones from their rough, unrefined state into stunning works of art. The natural stone fabrication process typically begins with the careful selection of materials. Fabricators often source their stone from quarries, ensuring that the chosen pieces exhibit the desired colors, textures, and grain patterns that will ultimately dictate the project’s final outcome.

Manipulating the Material into Various Shapes

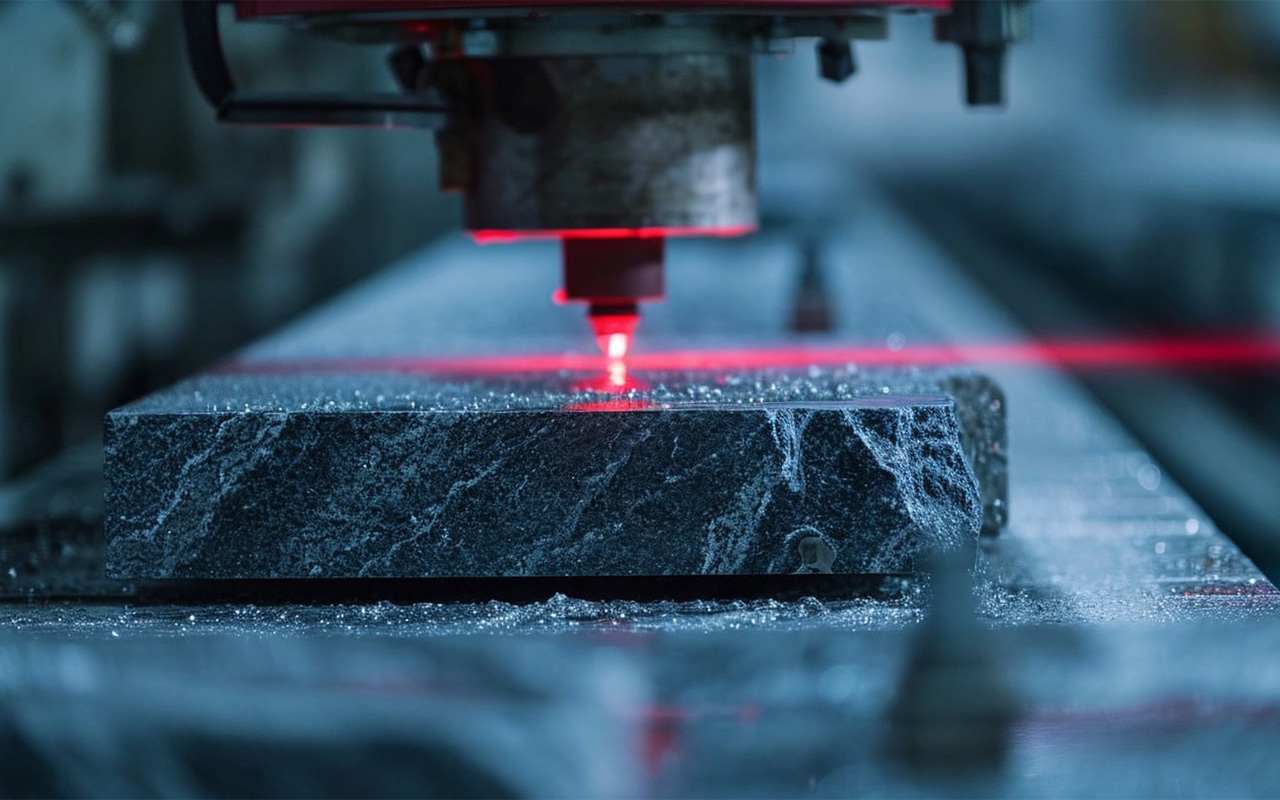

Once the stone has been sourced, the actual precision work begins. Utilizing a variety of tools, including diamond blade saws and CNC machines, artisans precisely cut the stone to size. The ability to manipulate the material into various shapes—from simple slabs to intricate designs—demands skill and an intimate understanding of the stone’s properties. Factors such as hardness, porosity, and the stone’s natural fissures must be considered during the shaping process to achieve the desired result without compromising the integrity of the material.

The Shaping Process

After cutting, the shaping process continues with detailing work that enhances the stone’s aesthetic appeal. Techniques such as polishing, honing, and flaming provide different finishes that cater to various aesthetic and functional requirements. Each method reveals unique characteristics of the stone, transforming it from a mere building material into a centerpiece that enhances any architectural or design space. Whether it’s a polished countertop in a modern kitchen or a rustic stone wall in a cozy home, the impact of well-crafted stone is undeniable.

Combining artistry and engineering in stone fabrication highlights the importance of precision work in creating enduring structures. As designers and builders recognize the value of natural materials, the impeccable craftsmanship in the natural stone fabrication process continues to be celebrated. From its origins in the quarry to its final installation, the journey of stone encapsulates a harmonious blend of nature and human creativity, resulting in timeless pieces that are both functional and visually captivating.

Polishing and Finishing Touches on Natural Stone

Polishing and finishing touches on natural stone are crucial steps in the natural stone fabrication process that significantly enhance the material’s aesthetic appeal and durability. After a piece has been quarried and cut into desired dimensions, it often undergoes various treatments to achieve the perfect sheen and texture. The process begins with grinding, using diamond abrasives that remove rough spots and inconsistencies. This stage prepares the surface and sets the groundwork for a flawless finish. It can dramatically alter the look of the stone, transforming it from raw material to a polished masterpiece.

Polishing

Upon achieving a smooth surface, the next step involves polishing, where fine abrasives are employed to create a high-gloss finish. The key to this phase is consistency and attention to detail, as varying pressure and technique can lead to uneven results. Factors such as the type of natural stone—granite, marble, or quartz—also significantly affect the desired finish. Each type has unique properties that can absorb or reflect light differently, affecting how the final product is perceived visually. This meticulous work beautifies the stone and enhances its resistance to staining and scratching, thereby extending the surface’s life.

Sealing

Finally, finishing touches such as sealing are essential to protect the stone from moisture and other environmental factors. A properly sealed natural stone looks more vibrant and functions better in kitchens and bathrooms where exposure to liquids is daily. During the natural stone fabrication process, applying the right sealant ensures that the stone retains its luster while preserving its natural beauty. Furthermore, this protective layer aids in simplifying the cleaning process, making it easier to maintain the stone as part of home or commercial decor.

Ultimately, the attention given to polishing and the finishing touches on natural stone can transform a simple piece into an elegant fixture that showcases the stone’s inherent beauty. Whether for countertops, flooring, or decorative elements, the care invested during fabrication culminates in a final product that resonates with quality and sophistication. This highlights the importance of skillful craftsmanship and understanding the properties of natural stone, ensuring that the results meet both aesthetic desires and practical needs.

Quality Control: Ensuring Standards in Stone Fabrication

In the world of construction and design, the significance of quality control cannot be overstated, especially in natural stone fabrication. The natural stone fabrication process involves multiple intricate steps, each requiring meticulous attention to detail to ensure that the final product meets both aesthetic and functional standards. From quarrying to polishing, every phase plays a critical role in defining the quality of the stone and its suitability for various applications, whether it’s for countertops, floors, or architectural facades.

The Selection of Raw Materials

Quality control begins at the inception of the natural stone fabrication process, starting with the selection of the raw materials. Experienced fabricators must assess the stone for any inherent flaws, such as cracks or inconsistencies in color and texture. This initial inspection is vital, as these imperfections can compromise the integrity and appearance of the finished product. Employing state-of-the-art technology, such as laser measuring and 3D modeling, has become common practice, allowing for enhanced precision and minimizing waste during the cutting and shaping phases.

Evaluation

Quality control continues with rigorous checks at every stage as the fabrication progresses. After cutting the stone, fabricators evaluate each piece for accuracy and quality. Inspections at this point can prevent issues down the road, such as the need for costly repairs or replacements. Additionally, as stones are polished and finished, final inspections ensure they meet the high standards expected by clients and architects alike. The passion for craftsmanship and strict quality control measures result in stunning, durable surfaces that stand the test of time.

Ultimately, the careful implementation of quality control in the natural stone fabrication process is essential for delivering products that fulfill design visions and endure the rigors of everyday use. By prioritizing quality at every stage, fabricators can uphold their reputation and foster lasting relationships with clients, resulting in a thriving business environment within the natural stone industry. With evolving technologies and an unwavering commitment to excellence, the future of stone fabrication promises even higher standards and innovations in quality assurance.

Crafting Custom Designs with Natural Stone

Crafting custom designs with natural stone has become an increasingly sought-after skill in the world of interior and exterior design. The unique qualities of natural stone—its textures, colors, and patterns—allow artisans to create one-of-a-kind pieces that can transform any space into a work of art. From elegant countertops to stunning mosaics, the potential for creativity is boundless. By utilizing various techniques during the natural stone fabrication, designers can bring their visions to life, providing clients with personalized solutions that reflect their style and needs.

Selecting the Right Type of Stone

The natural stone fabrication process begins with selecting the right type of stone, depending on the desired aesthetic and functionality of the piece. Options like granite, marble, limestone, and slate each possess distinct characteristics that lend themselves to different applications. Once the stone is chosen, skilled craftsmen employ advanced tools and machinery to cut, shape, and finish the material to the specified dimensions. This meticulous attention to detail ensures each piece fits perfectly and highlights the stone’s inherent beauty.

Finishing Techniques

Furthermore, the versatility of natural stone allows for an array of finishing techniques, from honed and polished surfaces to textured and antiqued finishes. Each technique brings out different aspects of the stone’s appearance, creating diverse options for clients to explore. Designers can also incorporate additional elements, such as inlays or custom engravings, to further personalize their creations. By understanding the properties and capabilities of natural stone, fabricators can expand the possibilities of design, resulting in truly bespoke pieces that stand the test of time.

Embracing Nature’s Rawe Beauty

Ultimately, the craftsmanship involved in working with natural stone transcends mere aesthetics. It is about embracing nature’s raw beauty while also considering each design’s practical implications. Whether it’s a grand entryway or a cozy kitchen island, natural stone is a testament to the skillful combination of artistry and functionality. As trends evolve and the demand for custom designs continues to grow, the natural stone fabrication process remains at the forefront, allowing for endless innovation in the design world.

Installation: Bringing Your Natural Stone Countertop to Life

Once the stone has been fabricated, it’s time to prepare for installation. Proper preparation involves measuring the space meticulously to account for any irregularities and to ensure that the countertop will fit flawlessly. During this stage, it’s essential to prepare the underlying cabinets, ensuring they are level and structurally sound. Any adjustments needed must be made beforehand to avoid complications during installation. The excitement builds as the fabrication transitions to bringing the natural stone countertop to life in its new setting.

Proper Handling of Natural Stone

The installation begins with carefully placing the countertop onto the prepared cabinets. The weight and density of natural stone require precise handling, as each slab can weigh several hundred pounds. Professional installers will use specialized equipment to lift and maneuver the stone into position, ensuring accurate and stable alignment. Once the countertop is in place, seams between slabs, if necessary, are meticulously polished to create a seamless appearance, preserving the natural beauty of the stone.

Protecting Natural Stone

Finally, the finishing touches are applied, which may include sealing the stone to protect it from stains and spills and ensuring the edges are finished to perfection. This step adds to the durability and enhances the stone’s natural luster. The installation process is complete when homeowners can finally step back and admire the stunning result of their investment. This beautiful natural stone countertop elevates their space’s aesthetic value and stands the test of time.

Maintenance and Care Tips for Long-lasting Stone Surfaces

Maintaining and caring for stone surfaces ensures their longevity and aesthetic appeal. Natural stone surfaces, such as granite, marble, and limestone, are beautiful and durable when properly cared for. The first step to ensuring these surfaces stand the test of time is understanding the natural stone fabrication process, which involves careful cutting, polishing, and sealing. By appreciating the craftsmanship behind natural stone, homeowners can make informed decisions regarding the proper maintenance techniques necessary to preserve their beauty.

PH Neutral Cleaners for Natural Stone

One of the key maintenance tips for long-lasting stone surfaces is regular cleaning. Using a pH-neutral cleaner specifically formulated for stone is crucial, as acidic or abrasive cleaners can damage the surface and compromise its finish. Daily dusting and immediate attention to spills can help prevent stains and preserve the surface’s integrity. Additionally, sealing the stone surface every few years protects it from moisture and staining, contributing to its durability. Always consult the manufacturer’s guidelines to determine the right sealing frequency for your specific type of stone.

Heavy Impacts and Excessive Heat

Another important aspect of stone upkeep is avoiding heavy impacts and excessive heat. Natural stone, while strong, can crack or chip if subjected to heavy objects or sudden temperature changes. Using trivets under hot pots and avoiding cutting directly on stone countertops can help prevent damage. Moreover, incorporating soft mats or coasters under heavy objects can serve as an added layer of protection. With these simple precautions, homeowners can enjoy their beautiful stone surfaces without worrying about wear and tear.

Consult With a Professional

Lastly, it is advisable to periodically consult with professionals who specialize in stone maintenance and restoration. They can provide insight into the specific needs of your stone surface, ensuring that you maintain its looks and structural integrity. By following these maintenance and care tips and understanding the importance of the natural stone fabrication process, you can keep your stone surfaces looking stunning for decades, enhancing the beauty of your home.

Eco-friendly Practices in Natural Stone Fabrication

Natural stone fabrication has undergone significant transformations in recent years, particularly as awareness of environmental issues has risen. Traditional methods often involve heavy machinery and considerable waste, harming the environment and local ecosystems. However, many modern fabricators are now adopting eco-friendly practices that minimize their carbon footprint and better use resources. These practices not only promote sustainability but also help in creating high-quality stone products that are in line with consumers’ growing demands for environmentally responsible building materials.

Water Reclamation Systems

One of the most promising eco-friendly practices in the natural stone fabrication process is the use of water reclamation systems. These technologies allow fabricators to capture and recycle water used during cutting and polishing, significantly reducing water consumption. Additionally, by recycling stone dust generated during fabrication, companies can reduce waste and repurpose this material for landscaping or as a filler in construction applications. This conserves resources and demonstrates a commitment to reducing landfill contributions, thus promoting a circular economy.

Energy Efficiency

Another vital aspect of eco-friendliness in stone fabrication is energy efficiency. Many fabricators are transitioning to electric-powered machinery and utilizing renewable energy sources, such as solar or wind power, to reduce their reliance on fossil fuels. This shift lowers greenhouse gas emissions and can result in cost savings over time. Furthermore, sourcing stones locally helps reduce transportation emissions and supports regional economies, creating a win-win scenario for the environment and local communities.

Sustainability

Lastly, many natural stone fabricators increasingly focus on sustainability certifications and responsible materials sourcing. Engaging with suppliers prioritizing ethical mining ensures that the stones used are extracted with minimal environmental impact. By combining innovative fabrication techniques with a commitment to ethical sourcing, the natural stone industry can play a vital role in promoting beautiful aesthetics and environmental stewardship. As these eco-friendly practices continue gaining momentum, they set a new standard in the industry, ensuring that natural stone remains a sustainable choice for builders and consumers.

Conclusion : The Art and Science Behind Natural Stone Fabrication

Natural stone fabrication is a meticulous blend of art and science that transforms raw, unrefined materials into stunning architectural elements and fixtures. When a granite or marble slab is extracted from the earth, it embarks on a journey that marries traditional craftsmanship with advanced technology. The natural stone fabrication process involves a series of steps that require both an artistic eye and an understanding of the physical properties of the stone. This intricate procedure ensures that each piece retains its unique character while meeting the specifications of a particular project.

At the heart of the natural stone fabrication process lies the quarrying phase, where large stone blocks are extracted from the earth. This stage demands expertise to minimize waste and optimize the stone’s quality. Once the blocks are cut, they are transported to fabrication facilities, where artisans begin the real artistry of shaping and finishing the stone. Techniques such as diamond wire and bridge saws are employed to achieve precise cuts, creating the foundation for countertops, tiles, or decorative installations. Additionally, polishing the surface requires a deep understanding of both the material and the desired finish, as natural stones have varying levels of porosity and hardness.

Each piece crafted from natural stone tells its own story, thanks to the fabricators’ creative vision and the stone’s raw beauty. Customization is a significant aspect of natural stone fabrication, as designers and clients often seek unique profiles, edges, and finishes that reflect individual tastes and project requirements. Every scratch, polish, or edge detail reflects the skill and artistry involved in the fabrication process, making each installation as much a work of art as a functional component.

Moreover, the science of natural stone fabrication extends beyond cutting and polishing. As technology continues to evolve, so does the fabrication methodology. CAD (Computer-Aided Design) software allows for precise planning and visualization, while advanced machinery enhances efficiency and accuracy. This melding of artistry and technological innovation not only elevates the quality of the finished product but also promotes sustainability by optimizing material usage and minimizing waste. As a result, natural stone remains a timeless choice for design and architecture, embodying beauty and durability in every crafted piece.